Field Test Facility (FTF) Results

H2Gen® Reactor Proves Highly Robust and Flexible in Actual Field Operating Conditions

Watch our AISTech 2024 presentation video with results from our field demonstration plant.

The commissioning process carefully ensured all safety features and balance of plant processes were fully operational before raising the system temperature.

In December 2023, Blast Furnace Gas (BFG) with the typical composition shown below was introduced to the FTF for its initial run.

Typical BFG Constituents

|

Constituent |

% |

|

Carbon Monoxide (CO) |

22 |

|

Carbon Dioxide (CO2) |

20.0 |

|

Hydrogen (H2) |

7.0 |

|

Water (H2O) |

6.0 |

|

Methane (CH4) |

0.0 |

|

Nitrogen (N2) |

45 |

|

Argon (Ar) |

0.0 |

In line with pilot phase results, the FTF system successfully produced hydrogen directly from BFG during the initial campaign.

Hydrogen production was measured using two methods:

- The difference in steam input volume to the reactor and the water volume after separation from the produced hydrogen

- Direct flow measurement of hydrogen output after water separation

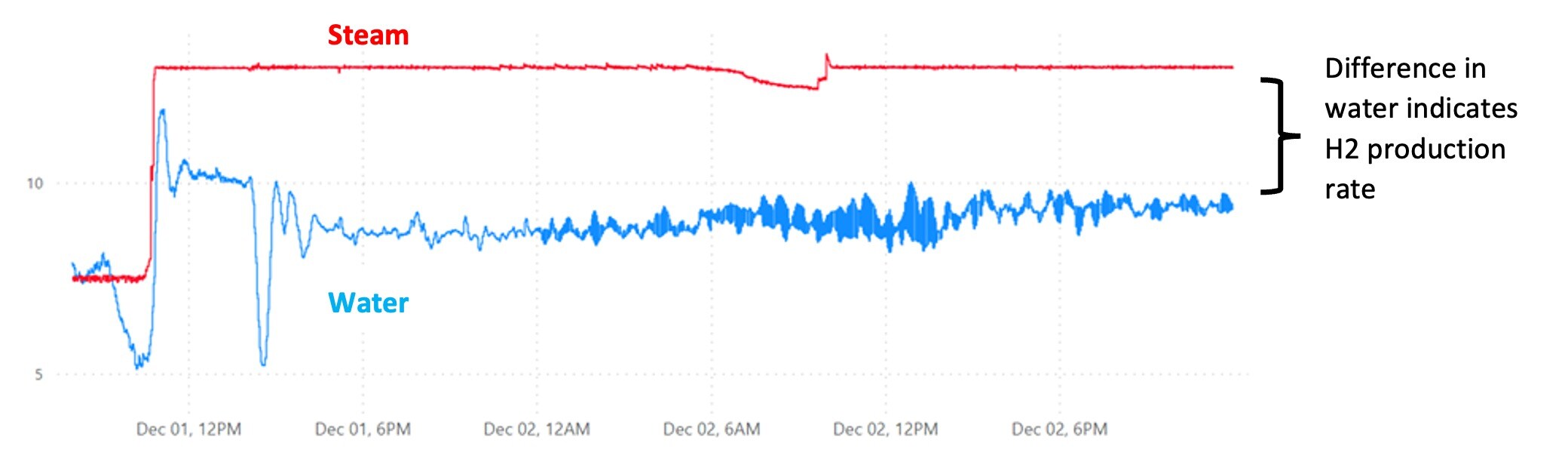

The figure below shows when H2 generation began in the system, with steam input remaining constant and water beginning to discharge. Before hydrogen production, steam and water flow rates are the same. During production, the difference in water and steam flow rates indicates the hydrogen produced.

Measurement of steam input and water output for hydrogen measurement

This validates hydrogen production and confirms that the reaction within the reactor cells on the cathode is occurring as expected, reducing steam to hydrogen. An oxygen ion is liberated and passes through the electrolyte to combine with CO on the anode side to form CO2.

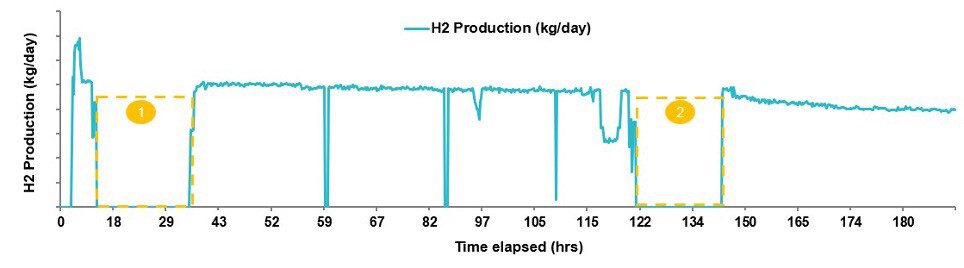

As expected, the comparison of this hydrogen production measurement method shows hydrogen production comparable to the direct measurement of hydrogen flow after water separation. The direct measurements results are shown below.

Hydrogen flow rate after water separation

Chart Notes:

- Controlled transition to feed gas interruption

- Planned hot standby due to sub-zero weather risk of freezing

Hydrogen production results have been consistent with expected production capacity at the given operating conditions. This promising outcome will be further verified with additional testing.

Conclusions

The significance of this milestone for improving industrial processes, mitigating greenhouse gases and creating multiple paths to an effective and affordable energy transition can't be understated.

Hydrogen has been and continues to be successfully produced directly from BFG without using separation methods to eliminate inerts from the feed gas. To our knowledge, this is the first time this direct conversion has been achieved. It represents a much better way for heavy industries to reach environmental and business objectives.